Medical

Capable Machines For A Demanding Industry

In a medical application as much effort is put into machining accurate and clean parts as there is into making good looking and cosmetically appealing parts. Swiss-type lathes meet every requirement asked of them. Swiss CNC machines have evolved into very versatile pieces of equipment, capable of making complex 3-D parts for the highly demanding medical industry.

Accurate, 3-D Designed Parts

One major technological leap for Swiss machining was the addition of reliable milling capability with live tooling. With this you have the ability to finish parts in the machine and eliminate secondary ops. One industry leader says “It also challenged our engineers and programmers to figure out ways to put machining center parts on the Swiss—parts like spinal plates, for example. If you can mill-turn a machining center part on a Swiss machine, you eliminate fixturing and workholding from the equation.”

From the cardiovascular and pacemaker business, to orthopedic and arthroscopic parts, 3-D capable Swiss-type CNC machines have the ability to do it all. Example of products you can make include bone screws, tiny tubes, fittings and valves as well as surgical drills, tabs, trepanning tools and bone plates. It comes down to the imagination of your engineers, a Swiss-type lathe knows no bounds.

High Quality, High Standards

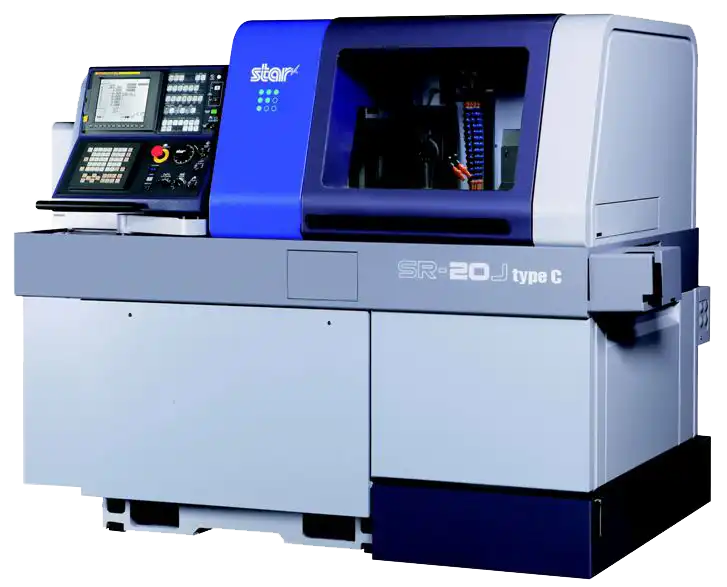

Medical applications and engineering are subject to validation and checks by the FDA. You have to be confident in a machines ability to pass these tests and to be able to meet government standards and STAR CNC’s are capable of passing these tests. Swiss-type CNC’s are capable of holding tight tolerances and the parts they produce are high quality and extremely accurate.

The ability to process these parts complete on the CNC Swiss machine helps the company meet the strict cosmetic requirements of the medical industry. “Parts must be accurate and burr-free, but almost as important in medical is they must look good” an industry insider was quoted as saying.